TUPDP Facilities

Small Scale Facility

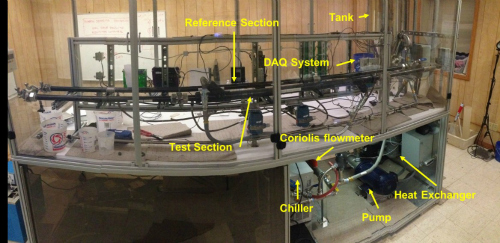

The small scale facility (pictured left) was built with a unique feature of three different diameters. This unique feature can be utilized in up-scaling studies. Moreover, this feature can be utilized to understand the effect of shear stress and Reynolds number on wax deposition process by keeping either one of the parameter constant in all the available three diameters.

The small scale facility (pictured left) was built with a unique feature of three different diameters. This unique feature can be utilized in up-scaling studies. Moreover, this feature can be utilized to understand the effect of shear stress and Reynolds number on wax deposition process by keeping either one of the parameter constant in all the available three diameters.

Recently the small scale facility was covered (pictured at left) and an air conditioner was installed to maintain the desired ambient temperature during testing conditions. The test sections are removable and can be reinstalled in the facility after the pigging process. In addition, this facility is an unmanned facility utilizing the latest process control system.

Recently the small scale facility was covered (pictured at left) and an air conditioner was installed to maintain the desired ambient temperature during testing conditions. The test sections are removable and can be reinstalled in the facility after the pigging process. In addition, this facility is an unmanned facility utilizing the latest process control system.

Specification of the Small Scale Facility:

Operating Temperature: 40° F-160° F.

Operating Pressure: 0-60 psig (tank); 0-500 psig (test sections).

Minimum Air Conditioner Temperature: 40° F

Flow Rate: 0-850 BPD.

Test Sections Diameters: 0.5 in., 1.0 in. and 1.5 in. (Nominal size).

Laboratory Scale Flow Loop

The laboratory-scale facility was built to evaluate the wax inhibitors with less material consumption and to conduct unmanned experiments to investigate the wax deposition mechanisms. The whole facility was built inside of a transparent cabin which can maintain a constant ambient temperature. This experimental facility consists of five components, test sections, a cooling system for the test section, a temperature control system, an electric power supply, and data acquisition system.

Operating Ranges:

Operating Temperature: 40 - 150°F

Operating Pressure: 0 - 60 psig

Flow Rate: 0 - 550 BPD

Pipe Diameters: 1.0 in.

Test Section Diameter: 0.5 in. and 1.0 in.

Airtight Tank Size: 15 gallons.

Dynamic Microscopic Flow Loop

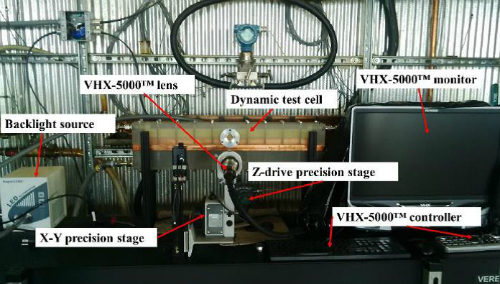

The purpose of the facility is to facilitate visual observation of wax deposition process under flow (dynamic) conditions. The test cell is designed such that the deposition occurs only along the bottom plate of the rectangular test cell. The temperature gradient is applied using water as coolant that flows countercurrent, in a rectangular conduit bottom to the test cell. The microscope can precisely measure the deposit crystals, giving information about the aspect ratio of crystals, size of crystals and distribution of crystals. Currently, the facility is used to measure the boundary layer thickness by measuring the precipitated particles from the wall.

Loop Dimensions: (length x Width x Height)

Oil chamber: 27”x2.25”x3”

Coolant chamber: 27”x2.25”x2.75”

Copper plate: 27”x2.25”x0.81”Operating Conditions:

Oil flow rate: 1 to 20 gpm

Oil temperature: 70° F -125° F

Water flow rate: 0.8 to 10 gpm

Water temperature: 50° F – 110° FMicroscope Specifications:

Magnification: 20X-200X

No. of frames per second: 10 to 50 frames per second (depends on magnification)

Type: VHX-5000TM with mounted Z drive

Cold Finger Apparatus

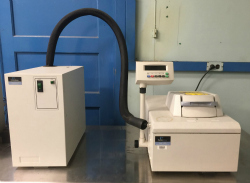

The cold finger apparatus has been extensively used by TUPDP to select testing fluids, investigate paraffin deposition mechanism, and screen wax inhibitors. Briefly, it contains a jacketed vessel and a cold finger probe. The oil temperature in the jacketed vessel and the cold finger probe temperature were maintained by two external chillers. The temperature difference between the oil and the probe will generate a gradient and provide the driving force for wax deposition. The oil in the vessel was homogenized with a Thermolyne Cimatec magnetic stirrer, which will generate a circular flow field around the cold finger probe to impose a shear on the surface of the cold finger probe.

The cold finger apparatus has been extensively used by TUPDP to select testing fluids, investigate paraffin deposition mechanism, and screen wax inhibitors. Briefly, it contains a jacketed vessel and a cold finger probe. The oil temperature in the jacketed vessel and the cold finger probe temperature were maintained by two external chillers. The temperature difference between the oil and the probe will generate a gradient and provide the driving force for wax deposition. The oil in the vessel was homogenized with a Thermolyne Cimatec magnetic stirrer, which will generate a circular flow field around the cold finger probe to impose a shear on the surface of the cold finger probe.

Operating Ranges:

Operating Temperature: 40 – 150° F

Rotational Speed: 60-1000 RPM

Cold Finger Probe Length: 1.77 in.

Cold Finger Probe Diameters: 0.67 in.

Stirrer Length: 1.49 in.

Stirrer Dimeter: 0.30 in.

Tank Size: 0.13 gallons.

Cross Polarized Microscope

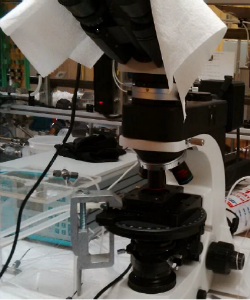

The Cross Polarized Microscope (CPM) is a part of the static test experiment used for analysis of samples in the static state. The CPM consists of a Z drive microscope with a 10x objective lens and 4 magnification lens of 5x, 10x, 20x and 50x. But due to limitations in the observation distance, the maximum magnification observed is 200x. The microscope is provided with cross polarizer and camera. The sample pane is attached with a temperature stage that can provide a controlled heating or cooling. Both microscope and temperature stage are connected to Graphic user Interface which enable proper image analysis of the wax crystals. The CPM is predominantly used for analyzing the crystal behavior in oil samples or deposit wax and measurement of Wax Appearance temperature.

The Cross Polarized Microscope (CPM) is a part of the static test experiment used for analysis of samples in the static state. The CPM consists of a Z drive microscope with a 10x objective lens and 4 magnification lens of 5x, 10x, 20x and 50x. But due to limitations in the observation distance, the maximum magnification observed is 200x. The microscope is provided with cross polarizer and camera. The sample pane is attached with a temperature stage that can provide a controlled heating or cooling. Both microscope and temperature stage are connected to Graphic user Interface which enable proper image analysis of the wax crystals. The CPM is predominantly used for analyzing the crystal behavior in oil samples or deposit wax and measurement of Wax Appearance temperature.

Specifications: Type: Z drive Objective stage size: L = 135.89 mm

W = 127 mm

H = 27.62 mm (15.11 mm up to sample chamber)Cooling/ Heating Rate: 0.1° C / hr (min)

50° C / min (max)Working distance from objective: 3.6 mm (minimum) Temperature range: -30° C to 120° C

Single-Phase Deposition Facilities

A test facility for conducting single-phase deposition tests was identified at the Alberta Research Council (ARC) in Edmonton, Alberta, Canada. The facility was shipped to Tulsa in 1995, reassembled, and significantly upgraded with new instrumentation, pumps, chilling system and a data acquisition and control systems. The test section consists of a near-horizontal, 50-m (164 ft) long, U-shaped pipe with an inside diameter of 43.6 mm (1.71 in.). This pipe is held in place with PVC centralizers in the center of a PVC pipe jacket with an inside diameter of 102 mm (4.0 in.).

A test facility for conducting single-phase deposition tests was identified at the Alberta Research Council (ARC) in Edmonton, Alberta, Canada. The facility was shipped to Tulsa in 1995, reassembled, and significantly upgraded with new instrumentation, pumps, chilling system and a data acquisition and control systems. The test section consists of a near-horizontal, 50-m (164 ft) long, U-shaped pipe with an inside diameter of 43.6 mm (1.71 in.). This pipe is held in place with PVC centralizers in the center of a PVC pipe jacket with an inside diameter of 102 mm (4.0 in.).

Operating Ranges:

Oil Temperature: 40 - 160°F

Oil Flow Rate: 0 - 2000 BPD

Oil Pressure: 150 psig

Glycol Flow Rate: 0 - 2000 BPD

Glycol Temperature: 40 - 160°F

Multiphase Test Facilities

A second test facility for conducting high pressure, two-phase, natural gas-oil deposition tests was designed, constructed and commissioned. The test section consists of a U-shaped, 52.5-mm (2.067) I.D., stainless steel pipe and is 48.8-m (160 ft) long. It is mounted on a boom such that any inclination angle between horizontal and vertical can be selected using a hydraulic hoist attached to an 18.3-m (60 ft) high tower. One leg of this test section is partially jacketed with a 10.16-cm (4 in.) nominal diameter CPVC pipe, over a length of approximately 16.2-m (53 ft). The entire test facility was designed for a pressure level of 6.8948 Mpa (1,000 psia) and temperature up to 180°F.

A second test facility for conducting high pressure, two-phase, natural gas-oil deposition tests was designed, constructed and commissioned. The test section consists of a U-shaped, 52.5-mm (2.067) I.D., stainless steel pipe and is 48.8-m (160 ft) long. It is mounted on a boom such that any inclination angle between horizontal and vertical can be selected using a hydraulic hoist attached to an 18.3-m (60 ft) high tower. One leg of this test section is partially jacketed with a 10.16-cm (4 in.) nominal diameter CPVC pipe, over a length of approximately 16.2-m (53 ft). The entire test facility was designed for a pressure level of 6.8948 Mpa (1,000 psia) and temperature up to 180°F.

Operating Ranges:

Oil Flow Rate: 0 - 4500 BPD

Gas Flow Rate: 0 - 2 MMscfd

Glycol Flow Rate: 0 - 3500 BPD

Oil & Gas Temperature: 40 - 160°F

Glycol Temperature: 40 - 160°F

Oil & Gas Pressure: 200 - 750 psig

Pipe: 2-in. ID Sch. 40 Stainless Steel Pipe

Flow Assurance Laboratory

This laboratory is located on the upper floor of The University of Tulsa Model Lab building on the North Campus. It houses all of the flow assurance related devices such as a DSC, HTGC, viscometers, oil-water separation, a hydrate cell, a cold-finger apparatus, etc.

This laboratory is located on the upper floor of The University of Tulsa Model Lab building on the North Campus. It houses all of the flow assurance related devices such as a DSC, HTGC, viscometers, oil-water separation, a hydrate cell, a cold-finger apparatus, etc.

DSC

Differential Scanning Calorimeter (DSC) used in TUPDP is Perkin Elmer Pryris 1, which was utilized to obtain the wax appearance temperature (WAT) and measure the wax fraction in the deposit. It is a power-compensated differential scanning calorimeter, the sample and reference material are each confined to a separate, self-contained calorimeter. The DSC features the fastest controlled heating and cooling rates, fastest equilibration for isothermal analysis, and calibration constancy. The PyrisTM Software helps to analyze the data. The DSC can detect the heat released from the crystallization process.

Differential Scanning Calorimeter (DSC) used in TUPDP is Perkin Elmer Pryris 1, which was utilized to obtain the wax appearance temperature (WAT) and measure the wax fraction in the deposit. It is a power-compensated differential scanning calorimeter, the sample and reference material are each confined to a separate, self-contained calorimeter. The DSC features the fastest controlled heating and cooling rates, fastest equilibration for isothermal analysis, and calibration constancy. The PyrisTM Software helps to analyze the data. The DSC can detect the heat released from the crystallization process.

HTGC

High Temperature Gas Chromatograph (HTGC) used in TUPDP is Agilent 7890A, with a capillary cool on-column (COC) and flame ionization detector (FID). It is usually utilized to analyze the composition information of crude oil or wax deposition. The capillary column used by TUPDP is Agilent J&W Capillary GC Column, with temperature limits of -60 °C to 400 °C. The column length, inner diameter and stationary phase thickness are 30 m, 0.32 m and 0.1 µm, respectively. The pressure maintained inside of COC is 10 psi, with the septum purge flow rate of 5 ml/min. The oven temperature, hydrogen flow rate, air flow rate, and Helium flow rate for FID front are 398 °C, 40 ml/min, 450 ml/min, and 5 ml/min, respectively. The volume of auto-sampler syringe is 1 µL, while the injection volume is 0.5 µL. The uncertainty of the deposit wax fraction data from HTGC is estimated to be ±0.015.

High Temperature Gas Chromatograph (HTGC) used in TUPDP is Agilent 7890A, with a capillary cool on-column (COC) and flame ionization detector (FID). It is usually utilized to analyze the composition information of crude oil or wax deposition. The capillary column used by TUPDP is Agilent J&W Capillary GC Column, with temperature limits of -60 °C to 400 °C. The column length, inner diameter and stationary phase thickness are 30 m, 0.32 m and 0.1 µm, respectively. The pressure maintained inside of COC is 10 psi, with the septum purge flow rate of 5 ml/min. The oven temperature, hydrogen flow rate, air flow rate, and Helium flow rate for FID front are 398 °C, 40 ml/min, 450 ml/min, and 5 ml/min, respectively. The volume of auto-sampler syringe is 1 µL, while the injection volume is 0.5 µL. The uncertainty of the deposit wax fraction data from HTGC is estimated to be ±0.015.